Screen wall to SS5/MH1 for a leading car manufacturer

Client: Vinci Construction for a leading car manufacturer i54 Wolverhampton

Area: MH1

Requirement: Screen wall to SS5/MH1

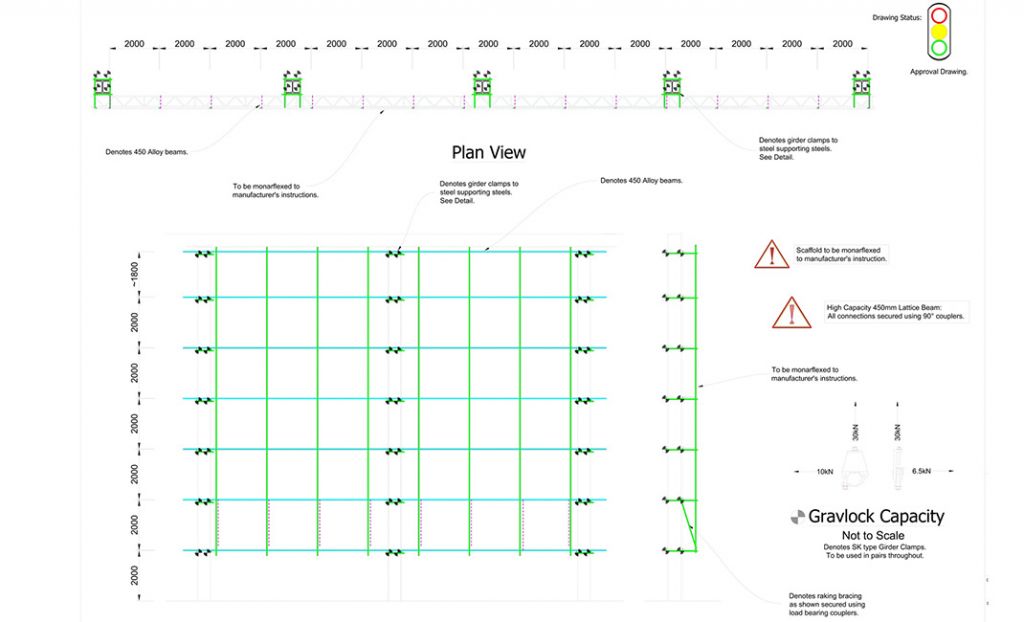

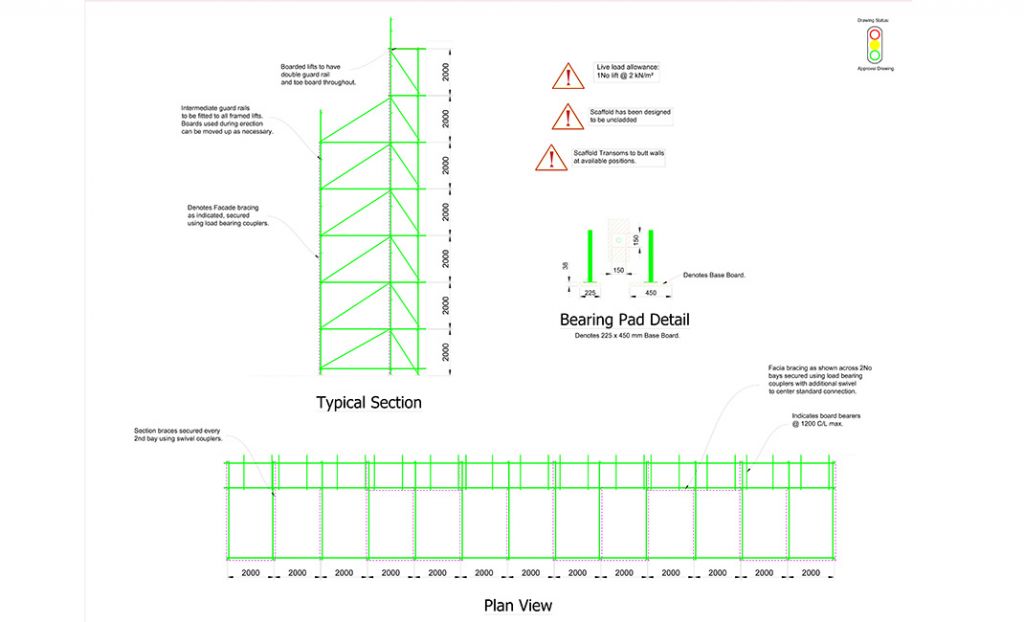

A scaffold screen wall was required to ensure a building end encapsulation for concreting works to be completed at floor level. Utilising 450mm high capacity lattice beams horizontally connected with drop forged right angled couplers and gravlock couplers to steel work at 8m centres, Airwright Midland were able to provide a water tight, suitable and sufficient scaffold screen that was encapsulated with flame retardant monarflex sheeting.

Related Projects

Loading bay at i54 Wolverhampton

A 5m x 6m on plan loading platform was required to be built on the spine roof to service the main roof area for JLR i54 Wolverhampton. Read more >>

Material Planning and Logistics canopy roof

A scaffold laydown was required to be built off existing steelwork to enable works at high level to ducting and cable trays. Read more >>

Access scaffold platform to SS5 Partition wall

A free-standing scaffold structure was required by VCUK to enable the completion of a Middas partition wall. Read more >>

Our housing development projects

We specialise in residential scaffolding solutions for a number of national housebuilders, and can deliver a high volume of supporting structures at any one time.... Read More >>

Queen Elizabeth Hospital

Airwright Midland provided internal and external access scaffolds to VCUK to enable the complete refurbishment.... Read More >>

Jaguar Land Rover, Lode Lane, Solihull

Airwright Midland provided VCUK full perimeter edge protection to new building, roof areas, lift shafts and stair cores.... Read More >>